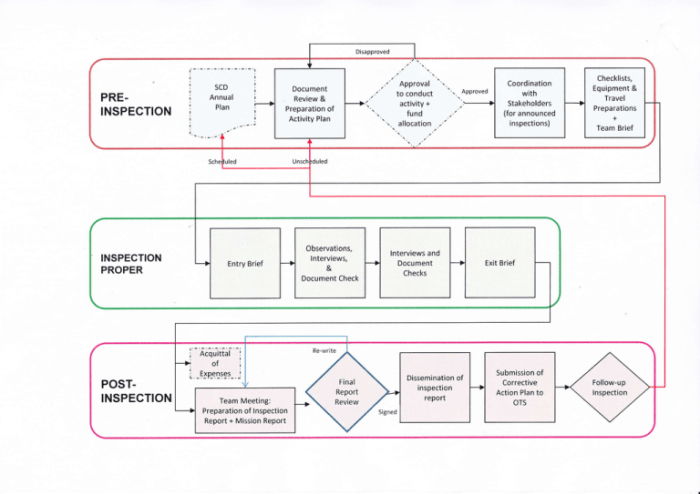

To ensure proper inspection deliveries should be scheduled during optimal time slots, a crucial aspect of maintaining accuracy and efficiency in the delivery process. This comprehensive guide delves into the significance of establishing clear guidelines, determining optimal inspection times, and fostering effective communication for thorough inspections.

By adhering to industry-standard inspection protocols, stakeholders can minimize errors, reduce delays, and enhance overall delivery outcomes. This guide provides practical insights and best practices to empower businesses in optimizing their inspection processes, ultimately ensuring the timely and accurate delivery of goods and services.

Proper Inspection Procedures

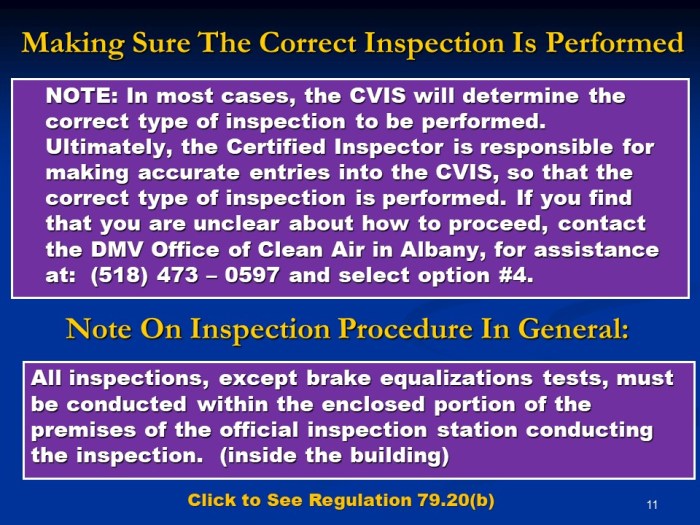

Establishing proper inspection procedures is crucial for ensuring accurate and efficient deliveries. Clear guidelines for inspection processes minimize errors, reduce delays, and guarantee the quality of products or services.

Industry-standard inspection protocols, such as the ISO 9001 quality management system, provide a framework for systematic and thorough inspections.

Scheduling for Optimal Inspection

Scheduling deliveries during appropriate time slots is essential for thorough inspections. Factors to consider include:

- Availability of qualified inspectors

- Volume and complexity of the goods being inspected

- Storage capacity and handling requirements

Inadequate scheduling can lead to rushed inspections, missed defects, and potential delays in delivery.

Communication and Coordination

Effective communication between stakeholders is paramount for proper inspection. Key parties include:

- Suppliers

- Inspectors

- Receivers

Clear communication channels, such as email, phone, or video conferencing, facilitate timely updates, resolve queries, and ensure a smooth inspection process.

Data Management and Documentation

Maintaining accurate records and documentation is crucial during inspections. Methods include:

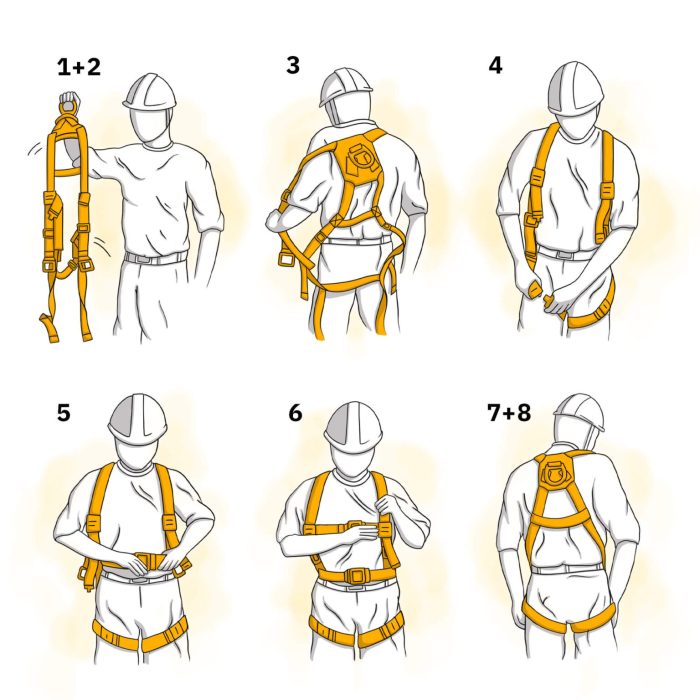

- Checklists

- Inspection reports

- Digital data capture

Proper data management ensures traceability, accountability, and compliance with regulatory requirements.

Continuous Improvement and Training, To ensure proper inspection deliveries should be scheduled during

Ongoing training and development are essential to maintain high standards of inspection. Methods include:

- Refresher courses

- Skill assessments

- Mentoring programs

Continuous improvement initiatives identify and address areas for improvement in inspection processes, ensuring their effectiveness and efficiency.

FAQ Overview: To Ensure Proper Inspection Deliveries Should Be Scheduled During

Why is scheduling inspections during optimal time slots important?

Scheduling inspections during optimal time slots ensures that there is sufficient time for thorough inspections, reducing the likelihood of errors and missed defects.

What factors should be considered when determining optimal inspection times?

Factors to consider include the complexity of the inspection, the availability of qualified inspectors, and the production schedule.

How can effective communication facilitate proper inspection?

Effective communication between stakeholders ensures that all parties are aware of the inspection requirements, timelines, and responsibilities.